Benefits of using a Digital Twin in Well Construction

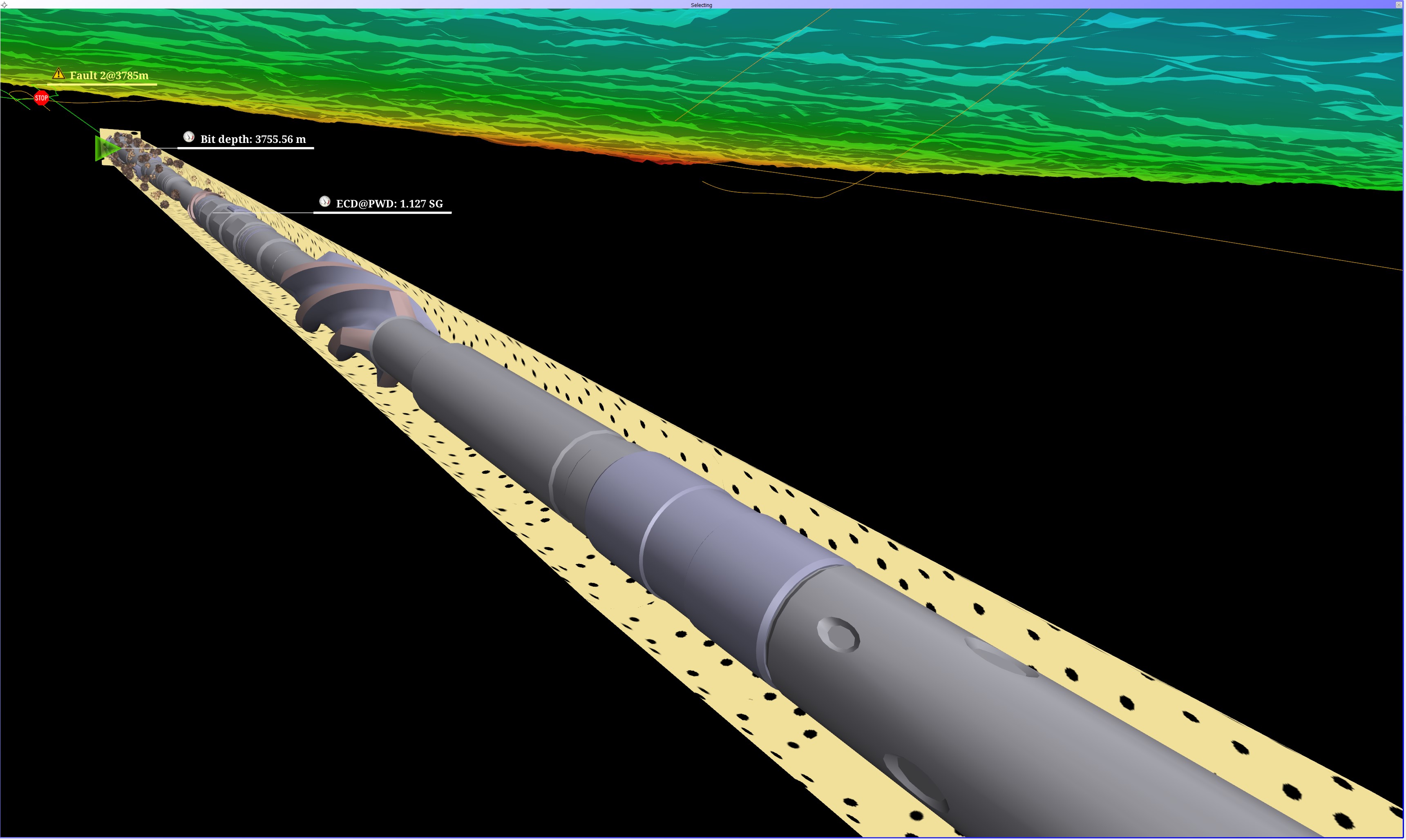

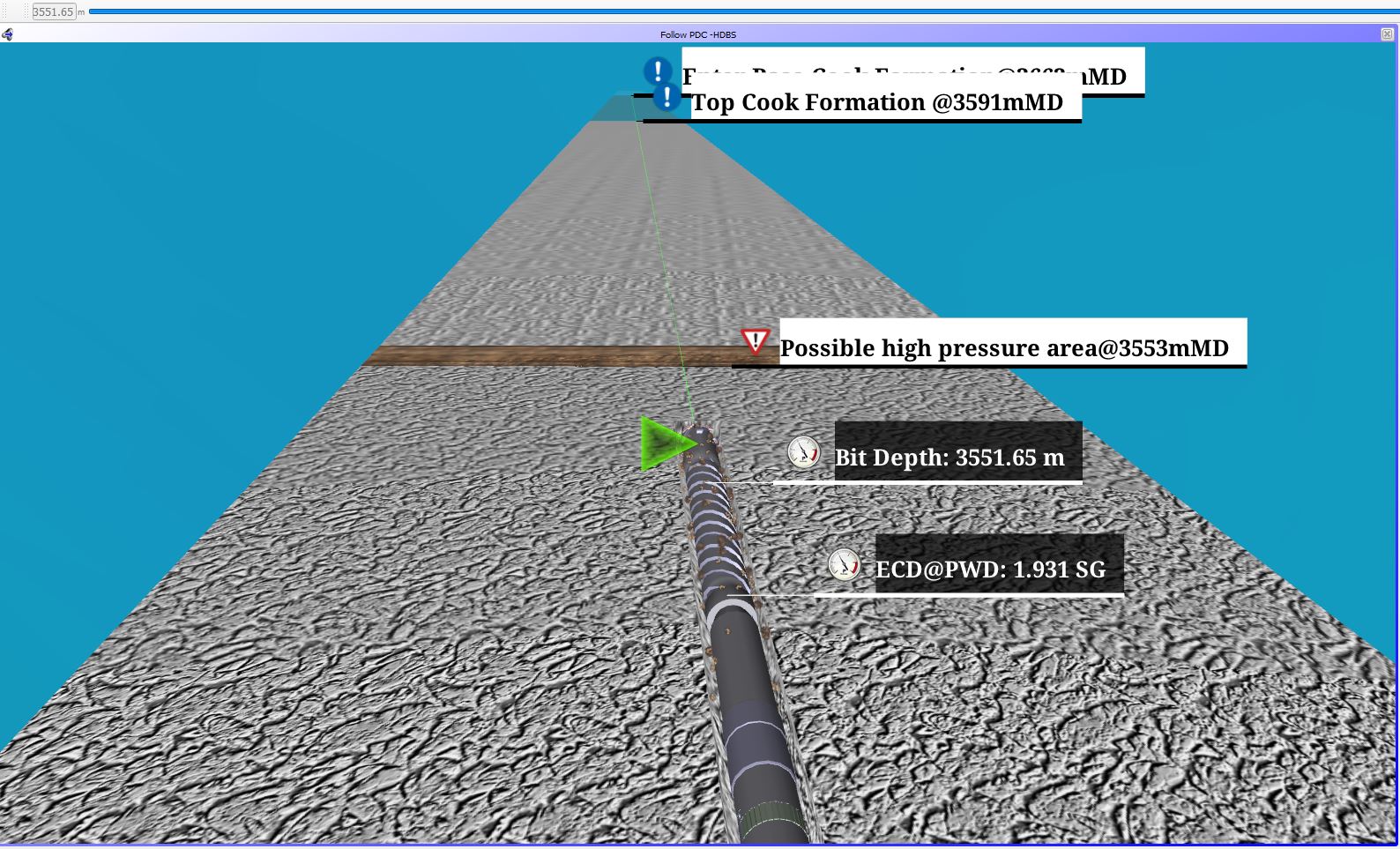

eDrilling uses dynamic drilling models and diagnostic technology merged with 3D visualization for a true digital twin or ‘virtual wellbore.’

—

Constructing wells are capital intensive in terms of financial, operational and reputational risks.

Artificial intelligence (AI) will be pivotal in leveraging both historical and new data from drilling operations to generate immediate, accurate and comprehensive insights for improved decision-making.

Digital twins provide unprecedented insight into drilling operations for planning, optimizing and monitoring with advanced analytics.

The technology allows creating a virtual model of the well that is constantly updated with real-time data and helps make dynamic and well-informed decisions. The technology provides a competitive edge for companies that adopt it, in terms of real monetary gains, improved safety and increased efficiency of drilling operations.

eDrilling uses dynamic drilling models and diagnostic technology merged with 3D visualization for a true digital twin or “virtual wellbore.”

Downhole GPS

eDrilling’s inaugural vision was to create a downhole GPS (i.e., Google maps for drilling operations). Convinced AI and machine learning technologies would represent a quantum leap in well construction, it has now become a paradigm shift in the oil and gas industry.

The software employs model-based reasoning in AI and predictive analytics to detect at a very early stage any anomalies, and it provides crew with warnings, notifications and diagnostic messages in good time to make the necessary adjustments. The software includes automated forecasting, forward-looking and what-if analysis, allowing for change in parameters and optimal drilling on the fly.

For example, well control events are avoided, and pressures are managed proactively. If there are potential influxes, the system detects very early indications, which are symptoms of a well control event, and also provide specific recommended actions for the driller to adjust and/or improve the situation. First actions are also provided directly to the control system to change the drilling plan.

Each event avoided will on average save one or more days and thus typically an estimate of 5 MNOK or more in the North Sea. Some operators have reported an increase in drilling efficiency by at least 10% and reduction in complex situations and accidents by 30% to 40%.

People and safety

An internal study researches the value of using digital twins in well construction and drilling operations used in more than 100 wells (to date, this research is continual). The results found that these wells had no hazardous incidents or any non-geological sidetracks, both of which are key priorities and objectives for most E&P companies around the world.

People and safety are the guiding principles when developing the software solutions, and the customers are happy about ridding themselves of the considerable costs associated with having to do sidetracks.

Digital twins represent the biggest opportunity available for performance optimization, avoidance of nonproductive time and hazard prevention in the energy industry.

Sustainability

Last but not the least, digital twins have proven to be a key enabler in improving the scorecard on sustainability for well construction through less carbon footprint by reducing overall drilling time; encouraging and bringing confidence to contactless advisory and collaboration; and its potential application to activities such as geothermal drilling.

Long seen as a temporary measure (due to initial pandemic lock-down), physical distancing habits seem like they are going to stick. Consequently, demand for contactless and/or low-touch activities are on the rise as well as a requirement for mostly all product delivery and services to be less contact and touch.

By enabling remote advisory, remote collaboration and long-distance (team) learning, the eDrilling system answers the challenges of the new world of work and helps ease and accelerate workforce transformation.

addresses the industry’s need to improve safety margins and reduce

addresses the industry’s need to improve safety margins and reduce