Study show no hazardous incidents, nor any non-geological sidetracks – on wells using a digital twin

Executive Summary

We researched 60+ wells where eDrilling’s digital twin technologies was used in i) preparations for well, ii) automated monitoring of well, and iii) real-time optimization of well – or a combination of these – and found that these wells had no hazardous incidents and no sidetracks.

Digital Twin

A Digital Twin is the digital representation of your actual well. Used in preparation it enables you to pre-drill your well. Used in real-time operation it enables you to do forward simulations and what-if simulations to detect mismatch and give input to change the drilling plan – to avoid problems, see and detect operational mismatches, and change parameters for optimal drilling (drilling the perfect well).

Methodology

We analysed 60+ wells were our technologies had been actively utilised in preparation and/or operation, and where we had correct and sufficient data to conclude on the hypothesis. Thus, 40+ of our digital twins in the period were omitted, due to availability (contractual, geographical, policy) of data.

Sidetracks, or avoidance thereof, was the focal area of the study, although the study also found that there had been 0 hazardous incidents on the 60+ wells analysed. «Geological surprises» as reason for having to do a sidetrack were omitted. Cuttings build up, collapse, washout, and packoff leading to plugging the well, were included.

We have had 5000+ participants in drill well in simulator prior to operations, with 150+ well specific scenarios. Automated Monitoring and Real time Optimisation is used in all drilling operations. This includes Tripping, Drilling, Casing/Liner operations and Cementing. It is also used in advanced operations like MPD and DGD.

Findings

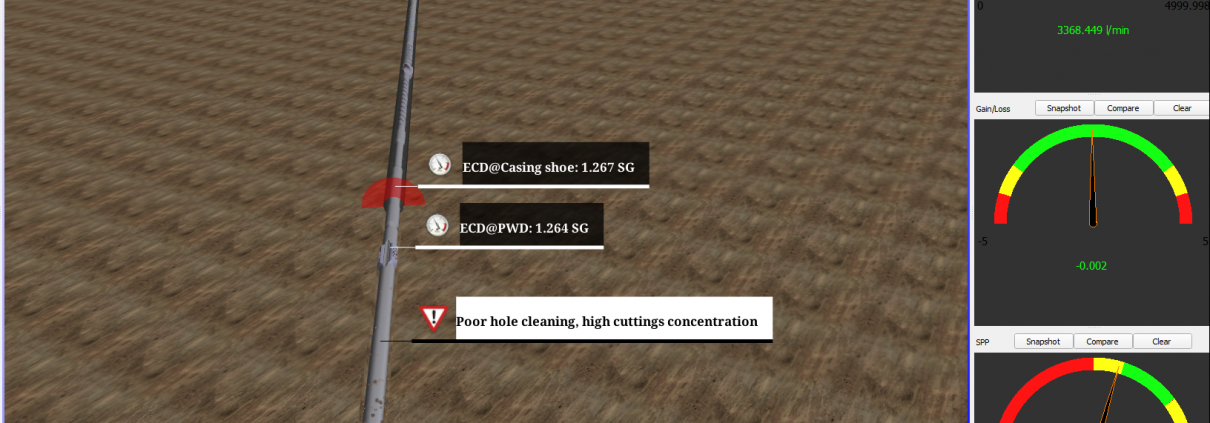

Of the 60+ wells analysed, 0 – zero – had to carry out a sidetrack. As the software at a very early stage detects anomalies, crews are provided diagnostics messages and notifications in good time to make the necessary adjustments.

Not a prime objective of the study, but included anyways as it continues to be a high priority for us, and for the industry as a whole, was avoidance of hazardous incidents. We are happy, and proud, to say that we had a 100% success rate here too.

Performance Optimization

We did not include performance optimization results in the study. Mostly because we, and our customers, wanted to have the study be as focused as possible, and not try to cover all aspects at the same time. That said, we have had some considerable success stories here too, with a European IOC estimating 19 days saved while drilling a vertical exploration well in the North Sea, as the most prolific.

Products involved

wəllSim hiDRILL is our solution for drill own well in simulator. wəllSim hiDRILL provides safe, effective, and efficient well delivery for any planned well by giving crew skills and experience on the specific well.

wəllAhead is eDrilling’s software solution for automated monitoring, real-time optimization, and live well support. It is designed for use on rig, in Real Time Decision Support Centers, and for any other individual or teams supporting live drilling operations. It is also the foundation of any future rig-side automation.

The post Study show no hazardous incidents, nor any non-geological sidetracks – on wells using a digital twin appeared first on Digital Twin.