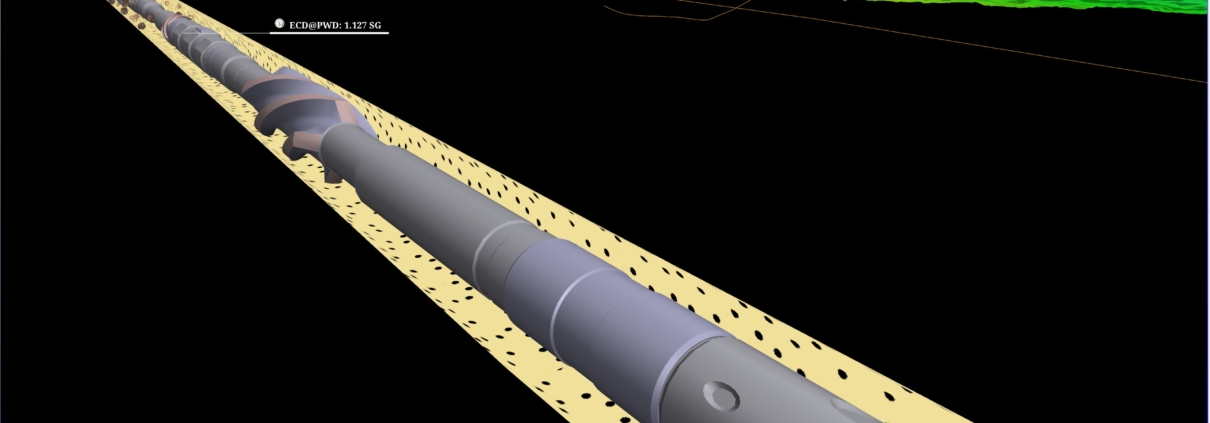

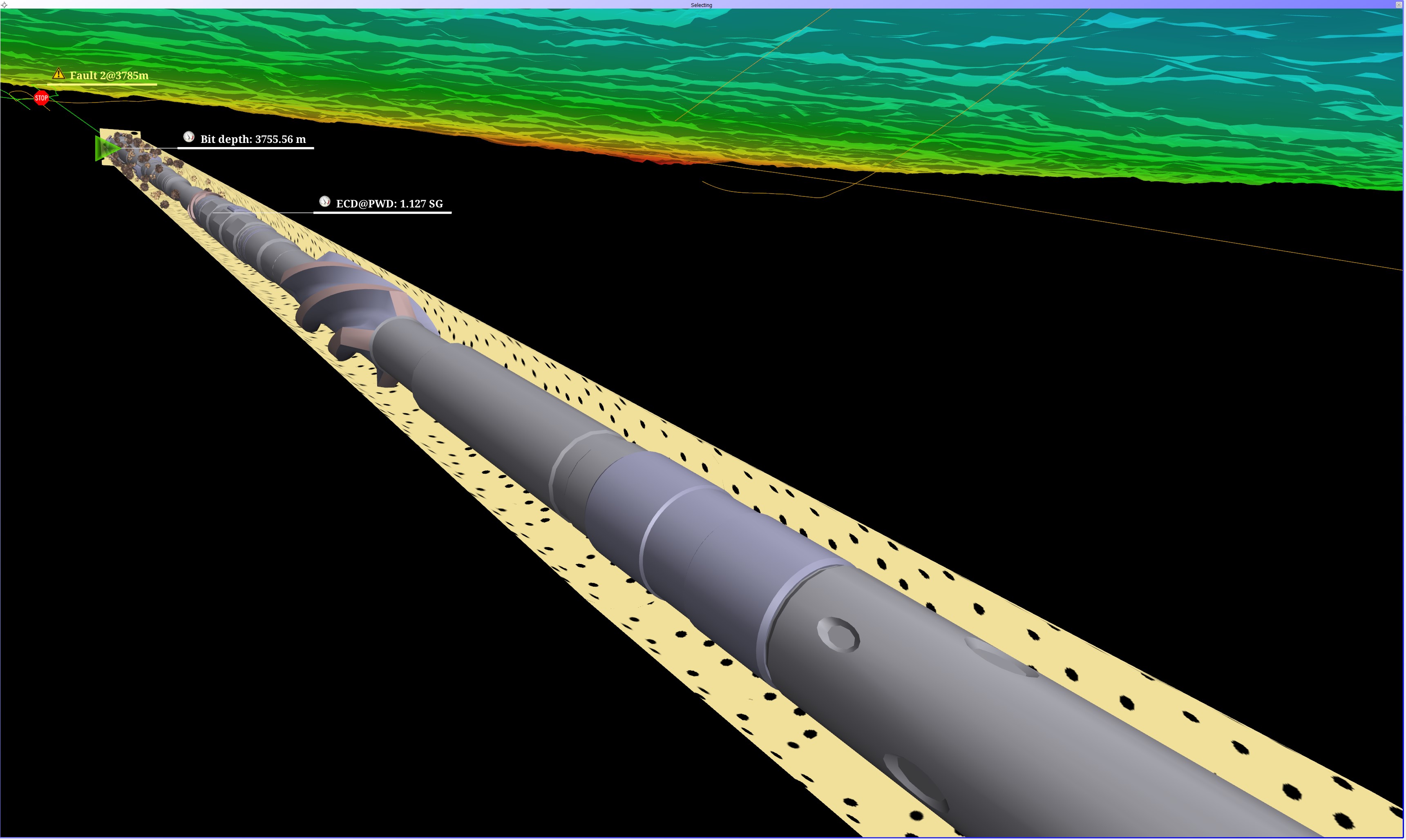

Artificial intelligence and digital twin software enables drilling automation

eDrilling is at the SPE Workshop: Delivering Value Through Automation this week in Bahrain. We are there to share how our artificial intelligence and digital twin software enables drilling automation, and how our downhole technologies are now coming together with rig systems .

We share how utilizing the same artificial intelligence and machine learning technologies in wellAhead, integrated with the rig’s Drilling Control System, our automated drilling control software will help keeping the operational parameters according to well limits. Enabling drillers to increase safety and optimize the performance of drilling operations.

eDrilling is a world leading supplier of AI, machine learning, and predictive analytics solutions to the oil and gas industry. We work closely with E&P companies, operators, and service companies to help them save cost, improve safety, and increase efficiency of drilling operations.

Our mission is to help energy professionals at E&P companies, operators and service companies reach their goals by providing drilling and well performance solutions needed to better plan, prepare for, perform and evaluate drilling operations.

Our vision dates back to the late 1980s, when we wanted to create a downhole GPS, or Google Maps if you like, for drilling operations. Convinced artificial intelligence and machine learning technologies would represent a quantum leap in well construction, we set forth what has become a paradigm shift in the oil and gas industry. For over 25 years, leading E&P companies, service companies, and drilling contractors, have leveraged the power of these technologies to improve drilling performance, onshore and offshore, deep water and shallow water, complex wells and factory drilling. Globally.

Hazard prevention

Prior to operations, eDrilling provides you with software to acquire skills and experience on you specific upcoming well, focusing on riskavoidance and handling. During operations, eDrilling software at a very early stage detects anomalies, crews are provided diagnostics messages and notifications in good time to make the necessary adjustments.

Performance optimization

Our software provides forecasting, forward-looking and what-if analysis, allowing for change in parameters for optimal drilling (drilling the perfect well).

NPT avoidance

As above, eDrilling uses aritifical intelligence and predictive analytics to foresee what will happen with your well. Software provides diagnostics and first actions to the crew (or directly to the control system), in order to change the drilling plan – to avoid problems

The post Artificial intelligence and digital twin software enables drilling automation appeared first on Digital Twin.